One of the facilities we offer at Oxford Hackspace is surface-mount electronic assembly and reflow soldering, the placement of solder paste and components on entire surface-mount circuit boards and their soldering all at once in a temperature-controlled oven. We recently completed a run of a small audio input board prototype, and to show you the process in detail we’re presenting it here.

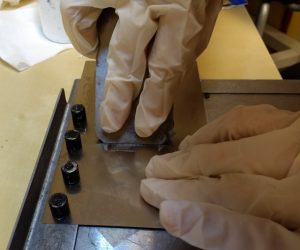

The first step in this process is to clean the PCBs, then to set up the solder paste stencil and apply the solder paste through it to coat each pad with a thin layer of paste. Care is taken to clean the stencil between boards, and to ensure that the stencil is aligned with the pads on each board. The full set of boards have paste applied to them, and are then arranged ready for component placement.

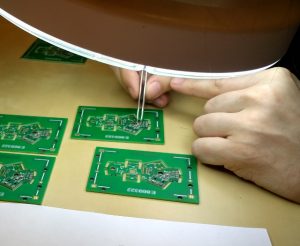

The components are placed by hand on the paste-covered pads, with one person placing and another person keeping the component supply running and identifying component positions.. The end result of this process is a row of boards with all surface-mount components in place, awaiting soldering.

Finally, the boards are placed in the oven in batches, and the temperature controller is set to step it through a preset temperature profile to reflow solder the boards. This profile is carefully chosen to minimise thermal stress on the components and board while still soldering all the pads.

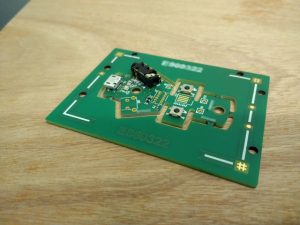

When the oven has finished its cycle, after about ten minutes, the boards can be removed and examined. The paste has turned into shiny solder joints, and all the components are attached to the board with good contacts. Any through-hole components will be added by hand at a later moment.

This run of nine fairly small boards was an afternoon’s work from first paste to final oven session. It is representative of the techniques available in the space, though we are capable of producing larger runs and of much bigger boards.